Questo sito web utilizza i cookie in modo da poterti offrire la migliore esperienza utente possibile. Le informazioni sui cookie sono memorizzate nel tuo browser e svolgono funzioni come riconoscerti quando torni sul nostro sito web e aiutare il nostro team a capire quali sezioni del sito ritieni più interessanti e utili.

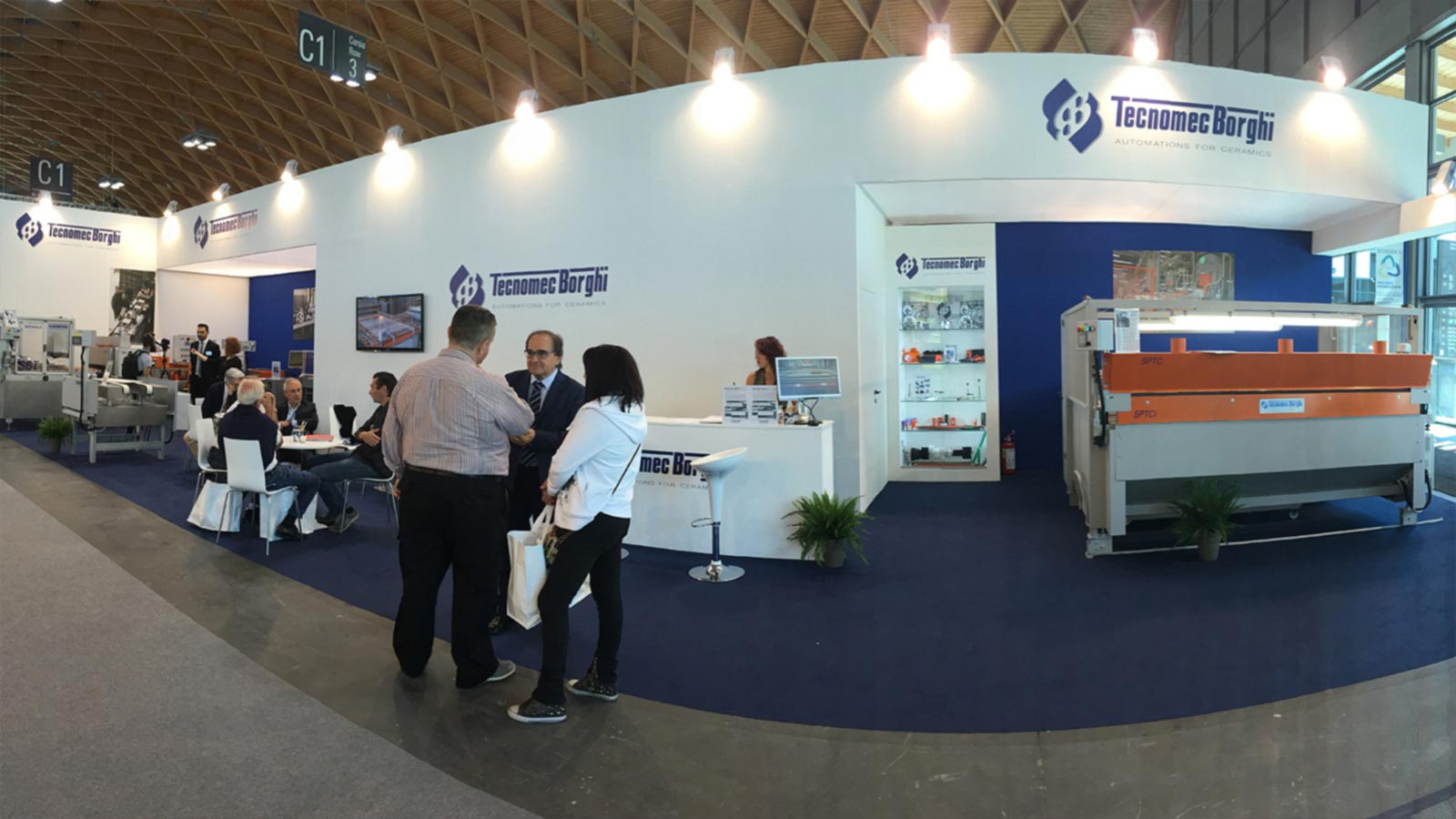

TECNOMEC BORGHI:

THE

AUTOMATED HANDLING EXPERTS

GET USED TO THE FUTURE

Since

1981 Tecnomec Borghi has specialised in automation for handling

products in the various stages of the production and logistics cycle.

The

company is established in the ceramic sector and also provides

multiple solutions for many other production industries, customised

and designed according to customer requirements, conveying its vast

know-how to other markets, such as food, beverage, construction,

packaging and logistics.

It

offers customers a full service, from design to production, up to

line testing. It also manufactures all the necessary accessories for

correct product positioning, guaranteeing spare parts and after-sales

service in Italy and abroad.

Specialists of satisfaction

Tecnomec

Borghi is distinguished for its customised and tailor-made solutions

for various types of production requirements.

Tecnomec

Borghi products are of higher quality than others, in terms of

materials and performance.

Customer-supplier

collaboration is fundamental for new solutions

to be created for the company to improve on the market.

Automated

handling systems for the ceramic industry

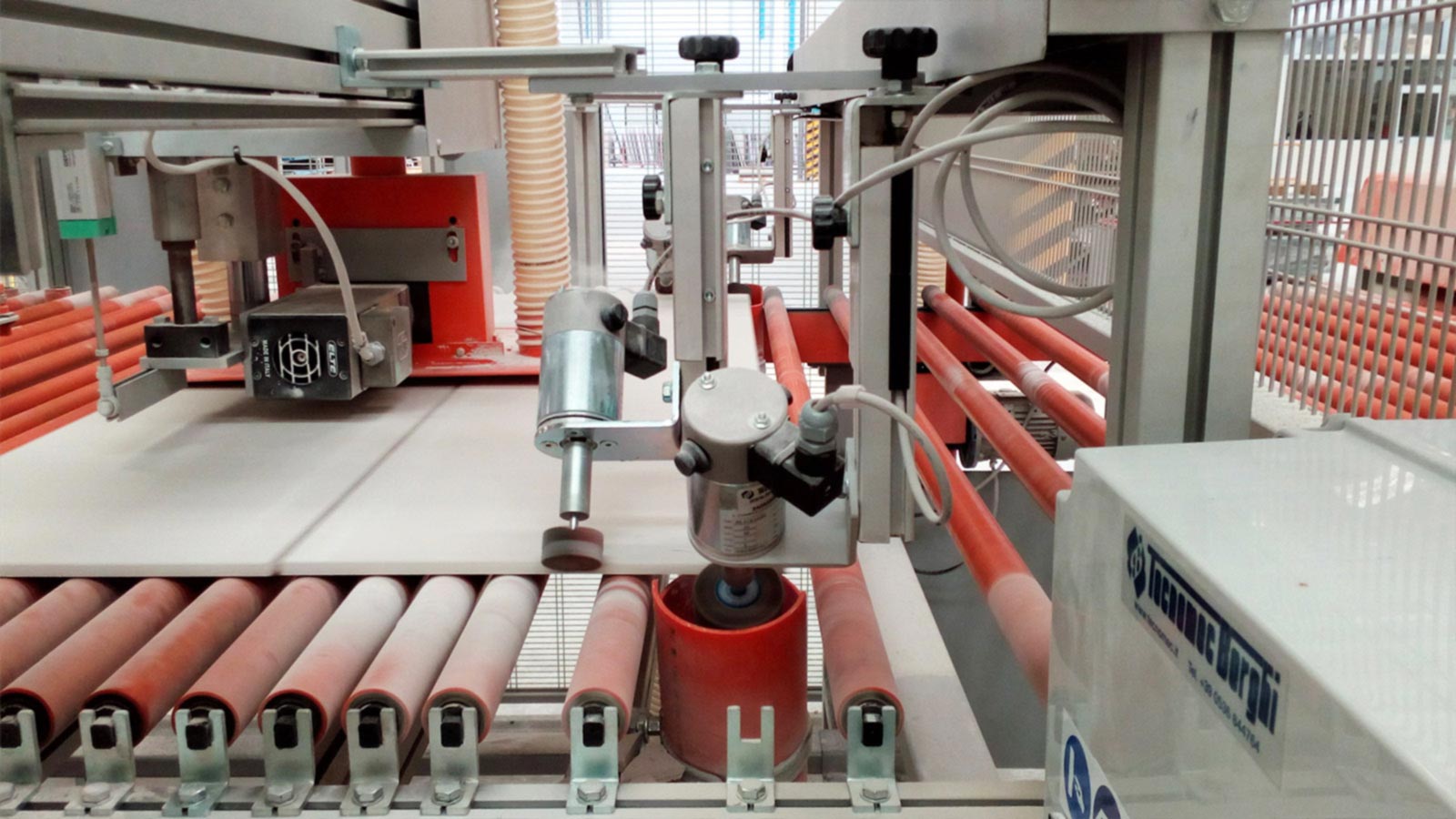

Tecnomec Borghi is

internationally known in the ceramic sector as one of the best

companies for designing and manufacturing lines with customised

solutions. It specialises in handling lines for tiles and

ceramic products, slabs, tableware and technical products.

The solutions consist of

the following, depending on the required customisation:

- Press output connection lines, loading and unloading dryer lines

- Accessories, walkers and tangential brushes

- Specific innovative and patented deburring systems

- Systems for drying

and eliminating liquids

Tecnomec Borghi products

are internationally known for their excellent reliability in terms

of:

- Maximum energy efficiency: thanks to being inverter-controlled with start&stop systems for energy saving.

- Long life: minimal wear of consumables (straps, belts, pulleys, shafts)

- Optimised and simple maintenance: option of programming during production stops, via modular electrical panels for independent management with inclusion or exclusion

In

addition, these systems are better value for money compared to

installation of standard products available on the market.

Tecnomec

Borghi is able to overcome the problem of restricted space available

to clients with the help of “multi-level” curves and lines,

developing projects on two levels where necessary. This delivers

significant savings throughout the entire life of the product thanks

to optimisation of space, lower consumption and quick routine

maintenance.

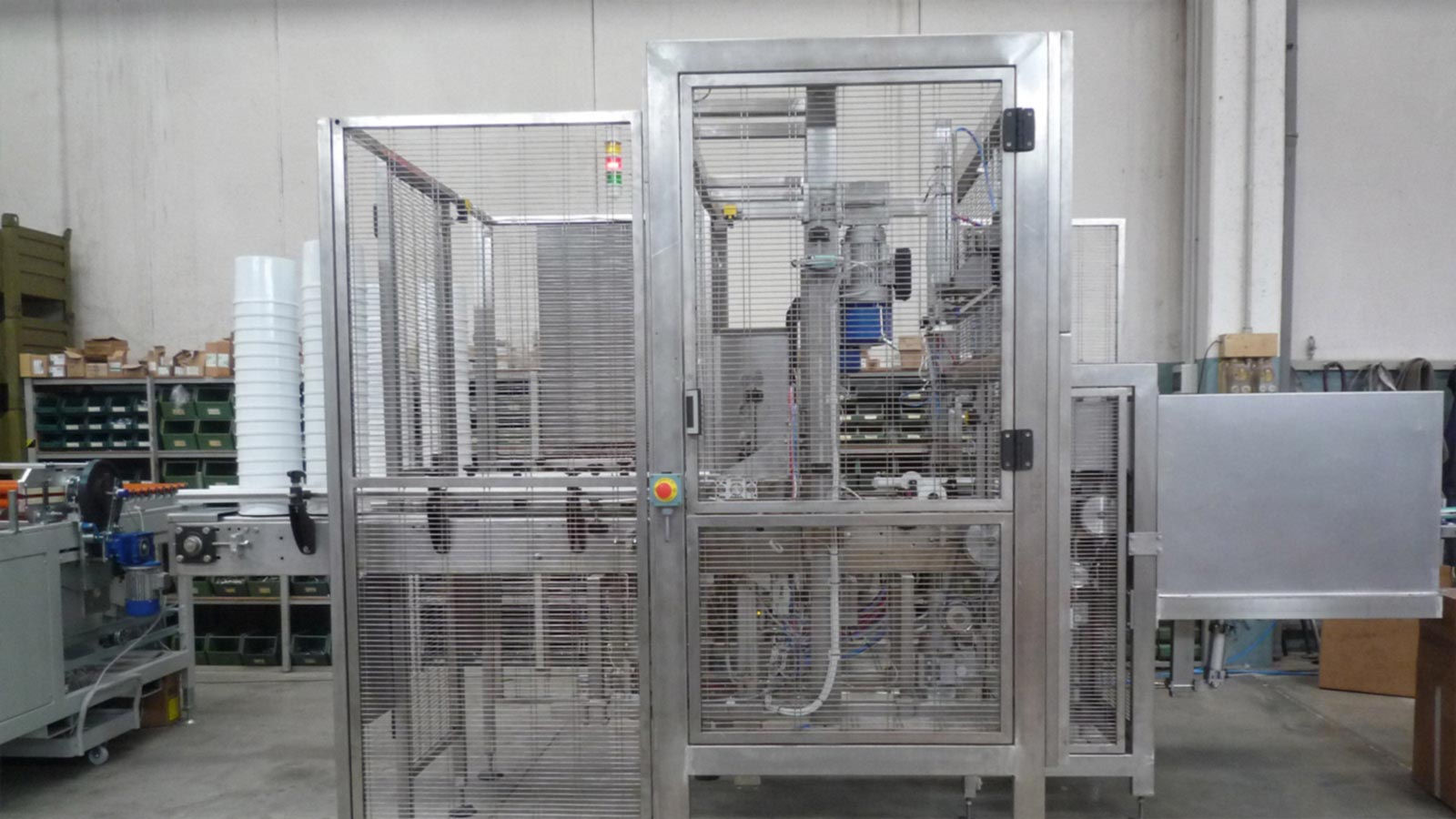

Automated

handling and cleaning systems for the food, beverage, building

materials and logistics sectors

The automated handling and

cleaning systems developed by Tecnomec Borghi in the ceramics

industry can be used in any production sector, without distinction.

If perfectly smooth transport is required, without wobbling, Tecnomec

Borghi lines resolve the problem, such as the automated transport of

marble slabs.

The company designs and

manufactures specific innovative deburring systems, such as diamond

scrapers, for many different materials, such as those used in the

cosmetics industry. If, on the other hand, the main problem is

cleaning the product, Tecnomec Borghi accessories can be customised

according to the shape of the product itself, for every surface to be

reached.

Like all Tecnomec Borghi

products, other production industries can also benefit from the

advantages offered:

- Maximum energy efficiency

- Long lasting

- Optimised and simple maintenance

- Optimisation of the space available

- Considerable savings compared to standard products

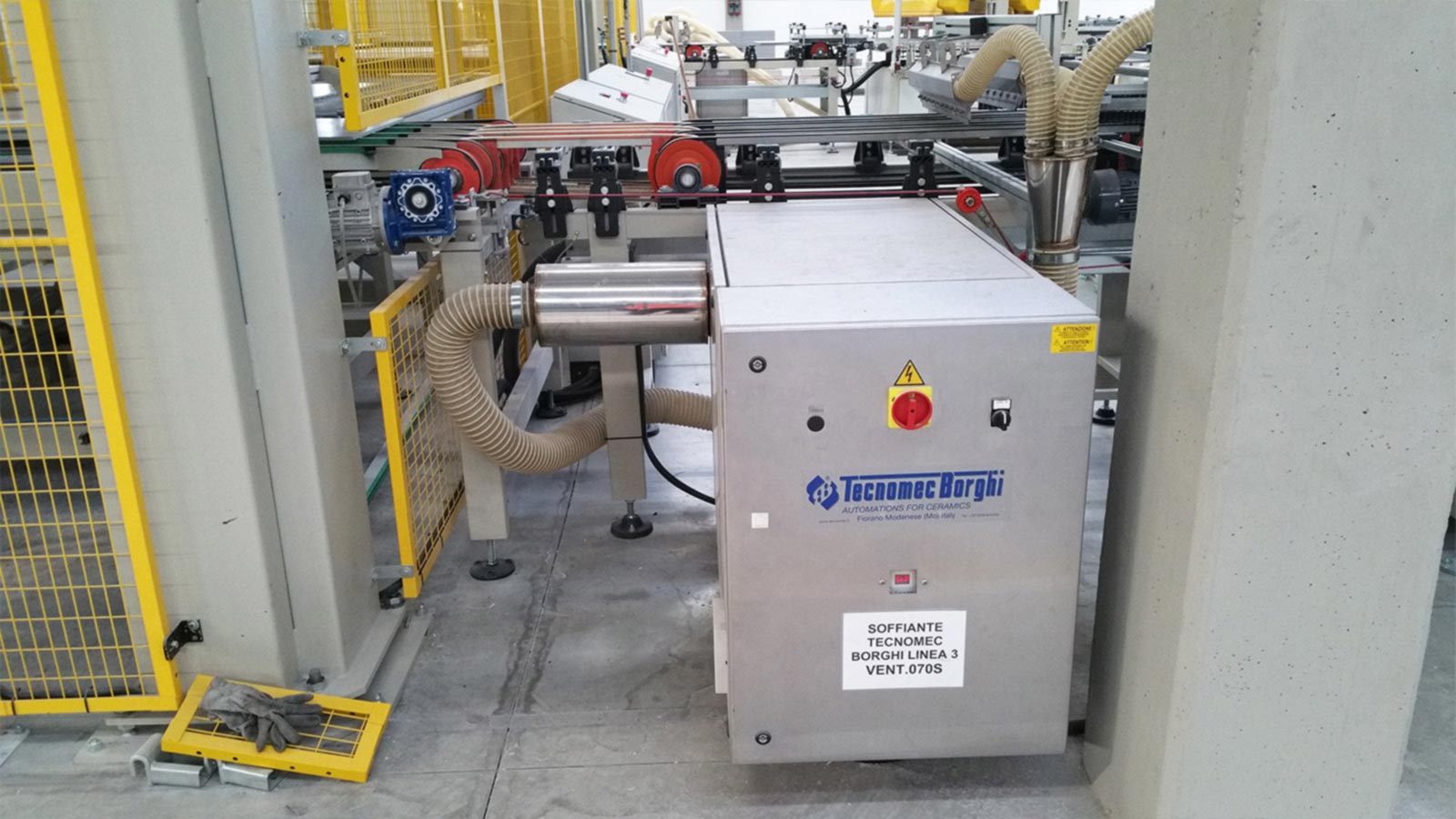

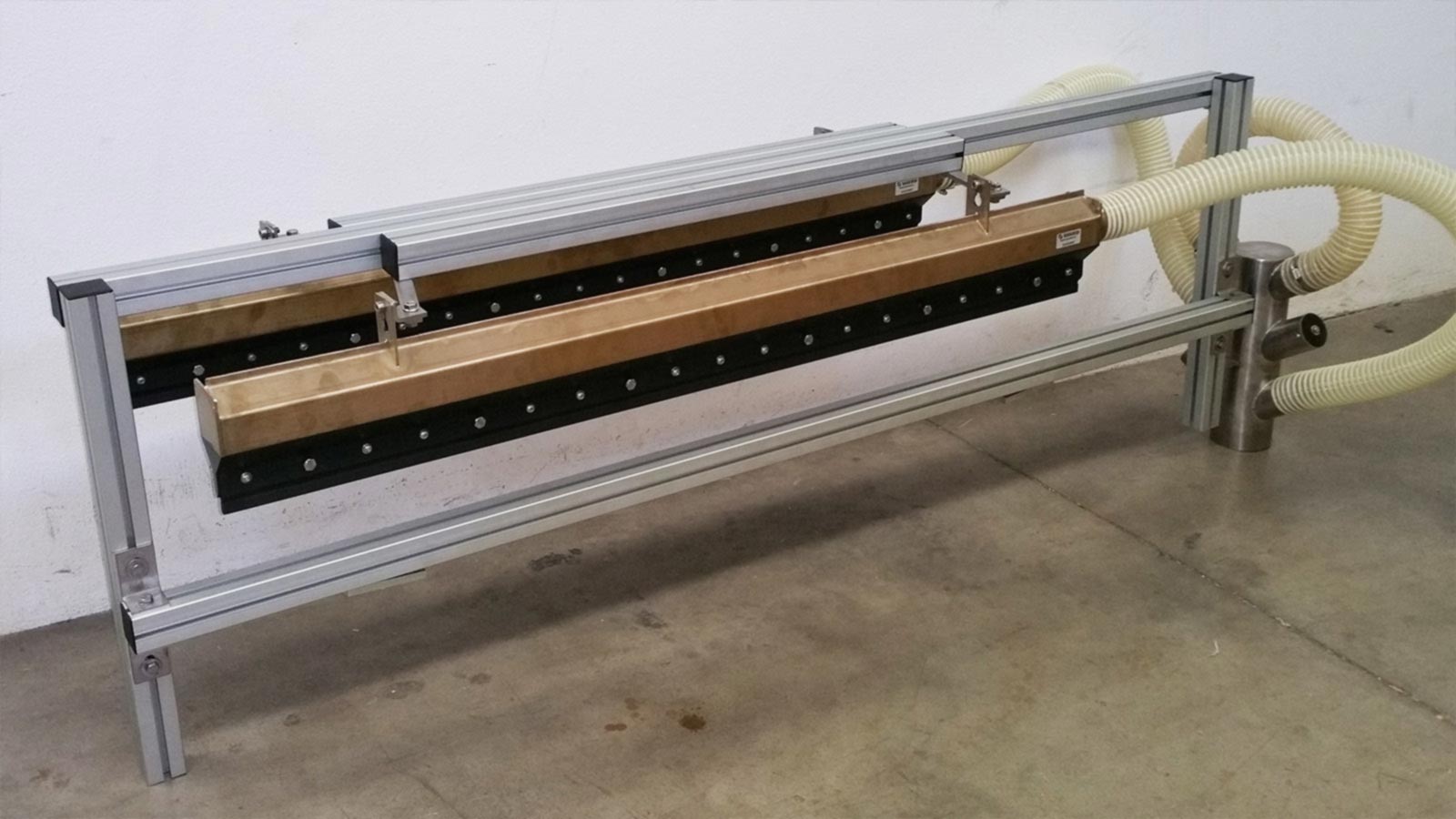

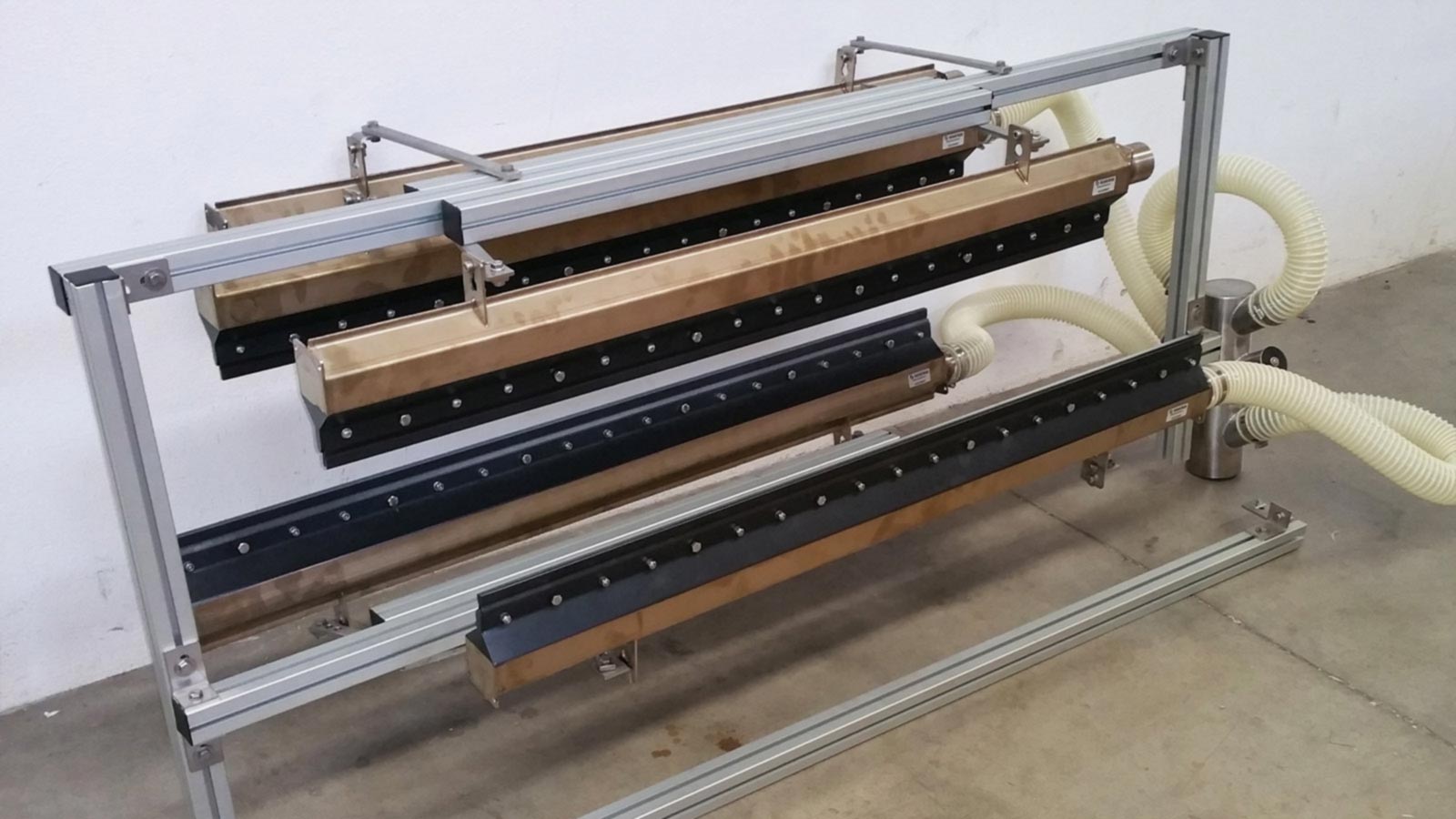

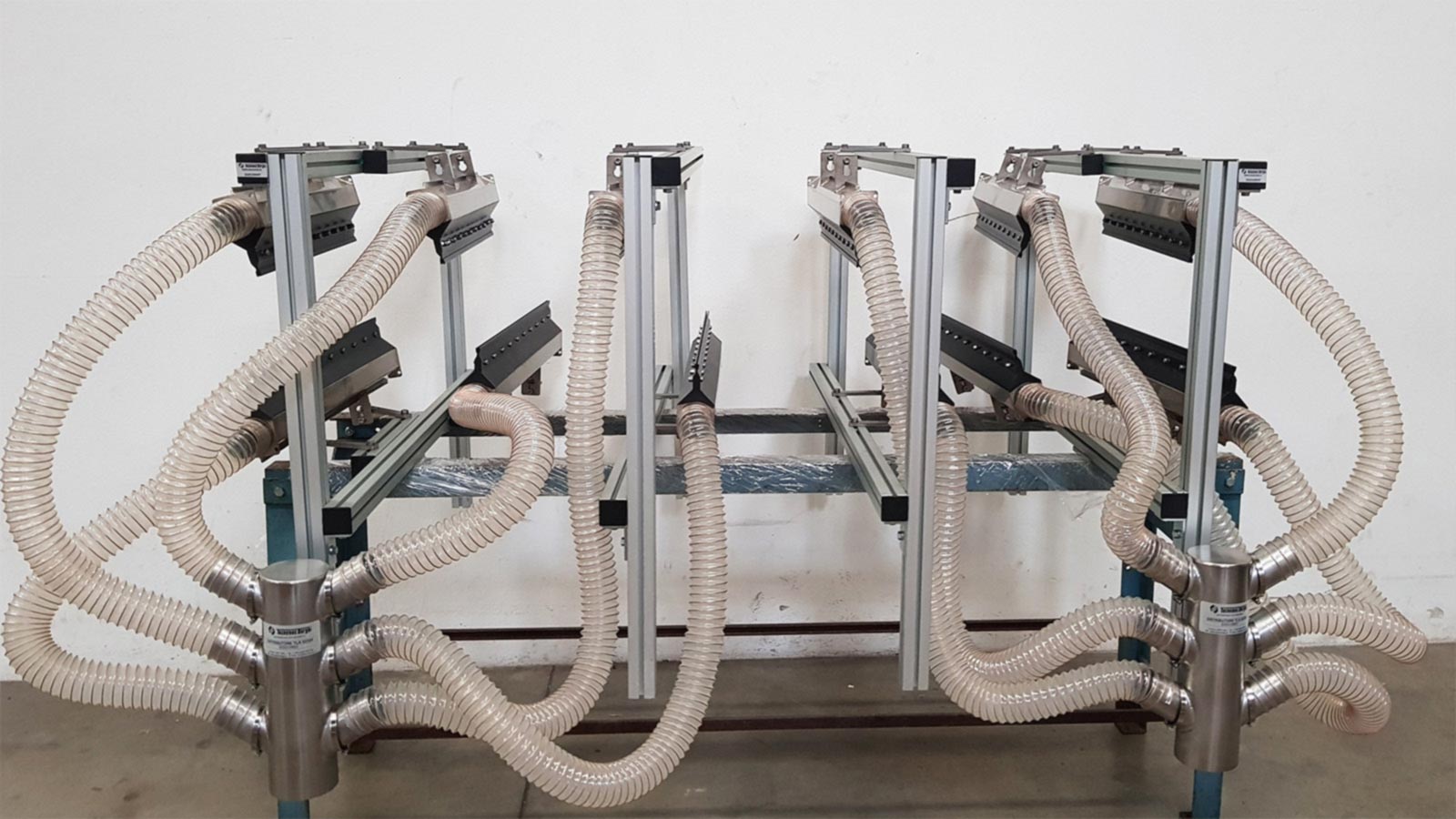

Tla

system to dry and eliminate liquids in the production industry

Tecnomec Borghi offers

solutions for all manufacturing industries that need to dry the

surface of any material from any type of production liquid (water,

condensate) or to eliminate it for the product to be adequate for

subsequent processing cycles.

The TLA system features an

air knife turbine with a blowing structure which, thanks to its

state-of-the-art accessories (draining rollers and various types of

blowing nozzles), can produce high volumes of air.

The specific nozzles with

special treatments ensure less dirt is produced during the processing

cycles and they are washed more easily.

Therefore, the customer

will enjoy simpler and faster routine maintenance, even in very dirty

environments, which results in great savings.

The nozzle has special

profiling that increases the air outlet speed and with the same

consumption, reduces operating times.

The filtering system, on

the other hand, is designed with specific filters, in accordance with

the various reference standards (example: FEPA filters for food).

Contact us

Enter your details in the

form below and you will be contacted by our sales department as soon

as possible. Getting in touch with us

is the best way to do business.

EN

EN IT

IT DE

DE